Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Evaluation of Load Response in Elastomeric Bearings Through Link Element and Finite Element Modelling

Authors: Shubham Sharma, Dr. Raghvendra Singh

DOI Link: https://doi.org/10.22214/ijraset.2024.65433

Certificate: View Certificate

Abstract

The Finite element modeling (FEM) and link element analysis of elastomeric bearings were conducted in this study to evaluate load behaviour and ensure compliance with design standards. A detailed FEM was developed, where material properties and boundary conditions were incorporated to simulate load transfer mechanisms, which were enhanced through link element analysis. Validation of results was performed against design codes and analysis software data, confirming the model\'s accuracy. A reliable method for optimizing elastomeric bearing design, improving structural safety, and meeting essential design checks was presented. Ten models in total were analyzed with variations, firstly the models were selected as per the design checks criteria. Then selected parameter’s output values are compared with each passed model case and then to finalize the research conducted, the data validation table has created with providing recommendations to show the suitability, aiming to improve design practices and address challenges in modern bridge engineering.

Introduction

I. INTRODUCTION - ELASTOMERIC BEARING

The field of bridge engineering is recognized as vital in infrastructure expansion, where the safe and efficient movement of people and goods across natural and man-made obstacles is ensured. Various dynamic loads, including vehicular traffic, wind forces, thermal expansion, and seismic activity, are experienced by bridges. To manage these forces and maintain structural integrity, specialized components, such as bearings, are required. Controlled movement between the bridge superstructure and substructure is allowed by bearings, and load distribution is managed to minimize stress on critical elements. Generally used elastomeric bearings are designed to handle vertical loads while permitting horizontal movement and rotation. These bearings are composed of alternating layers of rubber (elastomer) and steel shims, allowing vibrations to be absorbed, the effects of temperature changes to be mitigated, and deflections due to seismic and wind forces to be accommodated. A cost-effective and low-maintenance solution is provided by their flexible nature for various bridge types.

II. APPLICATION OF BEARING USING LINK ELEMENT ANALYSIS

The application of elastomeric bearings in bridge simulation is very difficult since it has not been possible for any analysis software that can analyse the layers between the Elastomeric bearing and its behaviour.

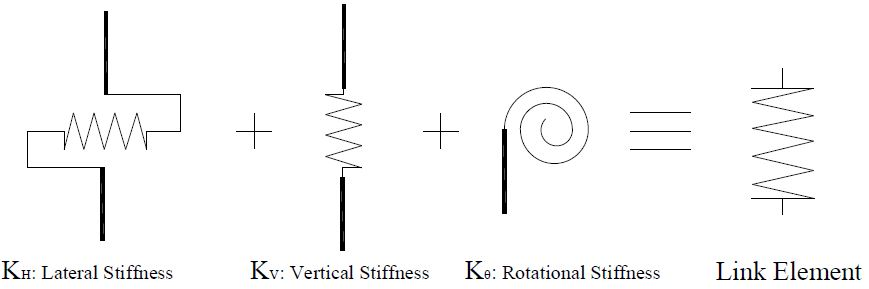

Fig. 1: Link elements used to perform the simulation

Figure 1 shown above is the analysis method to perform the elastomeric bearing simulation known as link element analysis, consist of lateral stiffness, vertical stiffness and rotational stiffness. Link element analysis allows for a more accurate representation of the load paths in elastomeric bearings by accounting for specific points of force transfer that are crucial for realistic load distribution in the model. By integrating this analysis into FEM, it refines the load behaviour simulation, leading to more precise predictions of performance under various loading conditions.

III. RESEARCH OBJECTIVES

On keeping in mind the above problem statement outlined for new research work for elastomeric bearing, the first and foremost thing is to check behavior in the analysis, it is recommended to take different Model cases considering the thickness of each layer of bearing as constant throughout all model cases and changing only bearing pad dimensions as variable. Then for accuracy in analysis, it has recommended to make the variants of each of the model cases. To simulate precisely, it has recommended to use the FEM analysis over each variants with loading used over the bridge should be highest as per IRC 6:2017. The current research has to pass through different design checks for the values obtained as per the output parameters decided. Then, the most stable cases list after passing the design tests can be taken into account that provides the recommendations that will make a feasible construction reference. Then the determination of output parameters for nodal behaviour like nodal displacement and DL and LL reactions, plate behaviour like maximum shear forces, bending moment and stresses in plate members and longitudinal girder behaviour like shear forces, bending moment and torsional moment as per simulation performed. Finally, to create the data validation table as per selected recommendation models using different output parameters.

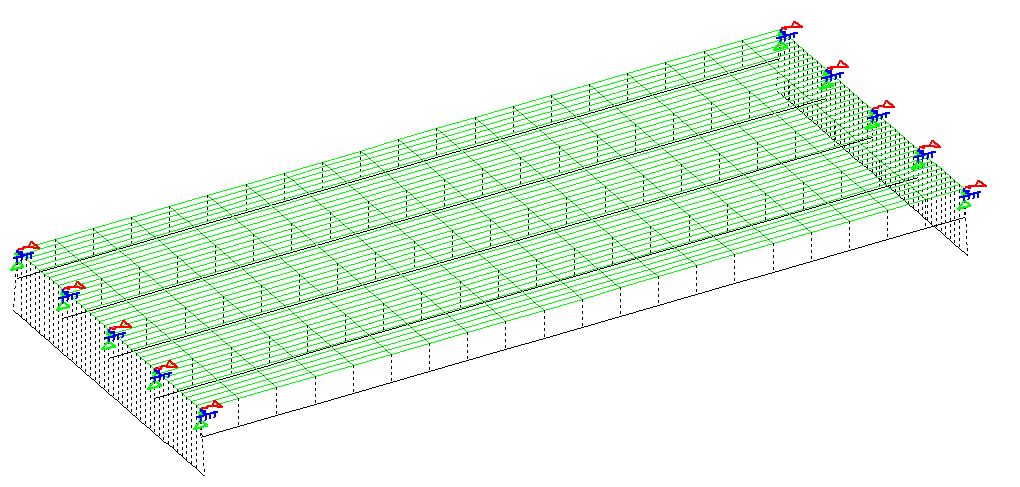

IV. 3D MODELLING OF THE STRUCTURE

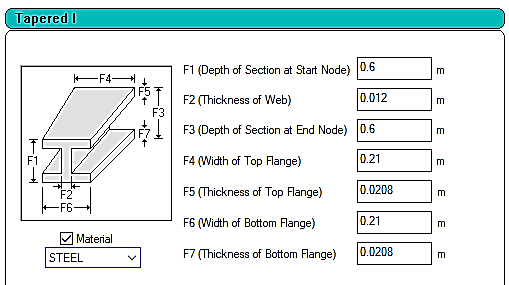

Comprehensive input data and its descriptions about the model given below. The input data used for creation of elastomeric bearing using link element using general data and loading data have applied to the structure such that the Vehicle width has taken as 2.79m along with dead load as self-weight and live load taken as IRC class 70R according to IRC 6:2017. The general data taken such as deck width has taken as 5m with deck span length of 12m respectively. The thickness of the deck has taken as 300mm, transverse girder properties has taken as 500mm x 300mm. The FEM analysis has taken into consideration while detailing the input parameter of the structure as quadrilateral type of meshing of 10 x 10 size. Beam taken as I section of material structural steel of taper in nature. M30 grade of concrete and FE 500 steel with shear modulus taken as 0.9N/sq. mm as per IRC 83, Table 1 and Modulus of Elasticity of Elastomer (E) has taken as 617263 KG/sq. m.

Fig. 2: Cross section of tapered I section with its physical dimention

Fig. 3: Plan view of bridge

Table 1: Various model cases used for analysis with subsequent variant and its configuration

|

Models framed for analysis |

Abbreviation |

Subsequent variant |

Variant Configuration |

|

Bridge deck supported over laminated elastomeric bearing with effective area of 160mm x 250mm |

Model 1 |

EB1A |

1E, 2O, 2S |

|

EB1B |

2E, 2O, 3S |

||

|

EB1C |

3E, 2O, 4S |

||

|

EB1D |

4E, 2O, 5S |

||

|

Bridge deck supported over laminated elastomeric bearing with effective area of 160mm x 320mm |

Model 2 |

EB2A |

1E, 2O, 2S |

|

EB2B |

2E, 2O, 3S |

||

|

EB2C |

3E, 2O, 4S |

||

|

EB2D |

4E, 2O, 5S |

||

|

Bridge deck supported over laminated elastomeric bearing with effective area of 200mm x 320mm |

Model 3 |

EB3A |

1E, 2O, 2S |

|

EB3B |

2E, 2O, 3S |

||

|

EB3C |

3E, 2O, 4S |

||

|

EB3D |

4E, 2O, 5S |

||

|

Bridge deck supported over laminated elastomeric bearing with effective area of 200mm x 400mm |

Model 4 |

EB4A |

1E, 2O, 2S |

|

EB4B |

2E, 2O, 3S |

||

|

EB4C |

3E, 2O, 4S |

||

|

EB4D |

4E, 2O, 5S |

||

|

Bridge deck supported over laminated elastomeric bearing with effective area of 250mm x 400mm |

Model 5 |

EB5A |

1E, 2O, 2S |

|

EB5B |

2E, 2O, 3S |

||

|

EB5C |

3E, 2O, 4S |

||

|

EB5D |

4E, 2O, 5S |

||

|

Bridge deck supported over laminated elastomeric bearing with effective area of 250mm x 500mm |

Model 6 |

EB6A |

1E, 2O, 2S |

|

EB6B |

2E, 2O, 3S |

||

|

EB6C |

3E, 2O, 4S |

||

|

EB6D |

4E, 2O, 5S |

||

|

Bridge deck supported over laminated elastomeric bearing with effective area of 320mm x 500mm |

Model 7 |

EB7A |

1E, 2O, 2S |

|

EB7B |

2E, 2O, 3S |

||

|

EB7C |

3E, 2O, 4S |

||

|

EB7D |

4E, 2O, 5S |

||

|

EB7E |

5E, 2O, 6S |

||

|

Bridge deck supported over laminated elastomeric bearing with effective area of 320mm x 630mm |

Model 8 |

EB8A |

1E, 2O, 2S |

|

EB8B |

2E, 2O, 3S |

||

|

EB8C |

3E, 2O, 4S |

||

|

EB8D |

4E, 2O, 5S |

||

|

EB8E |

5E, 2O, 6S |

||

|

Bridge deck supported over laminated elastomeric bearing with effective area of 320mm x 630mm |

Model 9 |

EB9A |

1E, 2O, 2S |

|

EB9B |

2E, 2O, 3S |

||

|

EB9C |

3E, 2O, 4S |

||

|

EB9D |

4E, 2O, 5S |

||

|

EB9E |

5E, 2O, 6S |

||

|

Bridge deck supported over laminated elastomeric bearing with effective area of 400mm x 800mm |

Model 10 |

EB10A |

1E, 2O, 2S |

|

EB10B |

2E, 2O, 3S |

||

|

EB10C |

3E, 2O, 4S |

||

|

EB10D |

4E, 2O, 5S |

||

|

EB10E |

5E, 2O, 6S |

||

|

EB10F |

6E, 2O, 7S |

|

Here, EB = Elastomeric Bearing, |

|

|

9A = Variant A for model number 9 |

2O = 2 Outer Elastomeric layer |

|

1E = 1 Elastomeric sheet layer |

2S = 2 Steel laminate layer |

V. RESULTS AND DISCUSSION

A. Design checks applied to bearing as per IRC 83:

This project started with the simulation for 70R loading on different elastomeric pad dimensions, comparing each model having each variants, some model variants are failed but some are passed. Details of passed variants are mentioned below:-

Table 2: Passed models recommendation

|

Model (Under 70R Loading) |

Area |

Thickness figure |

Thickness configuration |

Passed models |

|

|

Model 7 |

320 x 500 |

|

C |

3 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

4 steel laminates |

|||||

|

Model 7 |

320 x 500 |

|

D |

4 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

5 steel laminates |

|||||

|

Model 8 |

320 x 630 |

|

B |

2 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

3 steel laminates |

|||||

|

Model 8 |

320 x 630 |

|

C |

3 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

4 steel laminates |

|||||

|

Model 8 |

320 x 630 |

|

D |

4 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

5 steel laminates |

|||||

|

Model 9 |

400 x 630 |

|

B |

2 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

3 steel laminates |

|||||

|

Model 9 |

400 x 630 |

|

C |

3 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

4 steel laminates |

|||||

|

Model 9 |

400 x 630 |

|

D |

4 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

5 steel laminates |

|||||

|

Model 10 |

400 x 800 |

|

A |

1 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

2 steel laminates |

|||||

|

Model 10 |

400 x 800 |

|

B |

2 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

3 steel laminates |

|||||

|

Model 10 |

400 x 800 |

|

C |

3 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

4 steel laminates |

|||||

|

Model 10 |

400 x 800 |

|

D |

4 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

5 steel laminates |

|

Model 10 |

400 x 800 |

|

E |

5 elastomeric layer |

Pass |

|

2 outer layers |

|||||

|

Conclusion

This project concluded that the simulation for 70R loading on different elastomeric pad dimensions, comparing each model having different variants. The passed models are taken into consideration and compared them with respect of various parameters. Details of recommended variants are mentioned from table 3 to table 8 below:-

References

[1] Can Akogul et.al. (2008), “Effect Of Elastomeric Bearing Modeling Parameters On The Seismic Design Of RC Highway Bridges With Precast Concrete Girders”, The 14th World Conference on Earthquake Engineering October 12-17, 2008, Beijing, China. [2] Santoso, A. K. et. al. (2022). Structural Systems Comparison of Simply Supported PSC Box Girder Bridge Equipped with Elastomeric Rubber Bearing and Lead Rubber Bearing. Civil Engineering Dimension, 24(1), 19–30. [3] Aghelfard, A. et. al. (2019). Investigating The Performance Of Bridges Equipped With Elastomeric Bearings Reinforced With Fibre Under Traffic And Seismic Loads. Scientific Journal of Silesian University of Technology Series Transport, 104, 5–14. [4] Rubaee, S. K. A. et. al. (2019). Seismic Behavior of Composite Simply Supported Bridge Decks supported on Elastomeric Bearings. IOP Conference Series Materials Science and Engineering, 584(1), 012058. [5] Mustafa, S. et. al. (2020). Design of Rupture Strength of Side Blocks in Elevated Steel Girder Bridges with Elastomeric Bearings. International Journal of Steel Structures, 20(3), 885–896. [6] Erduran, E. et. al. (2022). Effect of Elastomeric Bearing Stiffness on the Dynamic Response of Railway Bridges Considering Vehicle–Bridge Interaction. Applied Sciences, 12(23), 11952. [7] Vasu Shekhar Tanwar, Sagar Jamle, (2018), \"Analysis of Box Culvert to Reduce Stress Values\". International Journal of Advanced Engineering Research and Science (ISSN: 2349-6495(P) | 2456-1908(O)), vol. 5, no. 5, pp.103-105 AI Publications, doi:10.22161/ijaers.5.5.14. [8] Sarita?, F. (2022). Effect of Elastomeric Bearings in Bridge Piers. DÜMF Mühendislik Dergisi. [9] Braga, G., et. al. (2020). Analysis of Neoprene Bearings on Requests and Strains. In International Journal of Applied Engineering Research (pp. 40–47) [Journal-article]. Research India Publications. [10] Bakhtiari, P., & Bargi, K. (2020). Seismic Vulnerability Assessment of High-Speed Railway Bridges Using Fragility Curves and Considering Soil-Structure Interaction. Civil and Environmental Engineering, 16(1), 39–48. [11] Xiang, N. et. al. (2021). Effect of bonding or unbonding on seismic behavior of bridge elastomeric bearings: lessons learned from past earthquakes in China and Japan and inspirations for future design. Advances in Bridge Engineering, 2(1). [12] Fediuc, D. O. et. al. (2015). Finite Element Modelling Of Elastomeric Bearings. Bulletin of the Polytechnic Institute of Jassy, CONSTRUCTIONS. ARCHITECTURE Section, 20–22. [13] Casarotti, C., et. al. (2008). STUDY OF A PHENOMENOLOGICAL MODEL FOR ELASTOMERIC BEARINGS [Conference-proceeding]. [14] Roshan Patel, Sagar Jamle, (2019), “Analysis and Design of Box Culvert: A Manual Approach”, International Journal of Advanced Engineering Research and Science(ISSN : 2349-6495(P) | 2456-1908(O)),vol. 6, no. 3, pp. 286-291, AI Publications, doi:10.22161/ijaers.6.3.3.7. [15] Vasu Shekhar Tanwar, Dr. M. P. Verma, Sagar Jamle, (2018), “Analytic Study of Box Culvert to Reduce Bending Moment and Displacement Values”, International Journal of Current Engineering and Technology, IJCET, Vol. 8, no. 3, pp. 762-764, DOI: https://doi.org/10.14741/ijcet/v.8.3.33 [16] Febymol, K., & Nair, R. (2017). Finite Element Analysis of Elastomeric Bearing. International Research Journal of Advanced Engineering and Science, 2, 175–178. [17] Deshmukh, N. V., & Waghe, Dr. U. P. (2015). Analysis and Design of Skew Bridges. International Journal of Science and Research (IJSR), 4(4).

Copyright

Copyright © 2024 Shubham Sharma, Dr. Raghvendra Singh. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65433

Publish Date : 2024-11-21

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online